In the mechanics of materials, the strength of a material is its ability to withstand an applied load without failure or plastic deformation. The field of strength of materials deals with forces and deformations that result from their acting on a material. ( strength of materials interview questions )

Introduction

The strength of material may broadly be defined as that branch of Engineering-Science which deals with the ability of various types of materials to resist its failure and their behaviour under the action of the forces.

Concept of Rigid and Non-Rigid Bodies

All physical bodies, such as engineering structures and machine part, can be classified either as rigid bodies or non-rigid bodies.

- Rigid Bodies:- A body is said to be a rigid body if there is no deformation occurs in the body. Like Piston, Connecting Rod, Engine Cylinder, etc.

- Non-Rigid Bodies: A body is said to be a non-rigid body if there is some deformation may occurs in the body. Like. Plastic, Wood, Paper, etc.

LOAD

Load may be defined as any force, which is applied on a physical body, and which may causes some amount of deformation in the body. The force that applied on a the body may be in the form of dead weight, friction force or an internal force generated within the body due to heating or cooling of the body

Types of Force/Load:-

- a) Tensile Force

- b) Compressive Force

- c) Shear Force

- d) Torsion Force

- e) Bending Force

The following points are worth to be noted:-

- 1. A tensile force always acts along the longitude of the specimen and brings about an increase in the length of the specimen and a decrease in the cross-section area of the specimen.

- 2. A compressive force always acts along the longitude of the specimen and brings about a decrease in the length of the specimen and an increase in the cross-section area of the specimen.

- 3. A shear force act along the surface of the specimen.

- 4. A torsion force acts about the axis of the specimen and brings about a resultant twist in the specimen.

- 5. Bending force brings about a resultant sag in the specimen, about its transverse sections.

Note: Forces generated due to heating or cooling of the specimen can either be tensile or compressive in nature, depending upon the type of supports associated with the specimen.

Elastic and Plastic Bodies

All physical bodies can also be classified as elastic or plastic bodies. Consider a body, upon which a certain load is being applied. Either of the following two cases can occur when the load is removed from the body.

- i) The body regains its original shape, after removal of the load. In this case the body will be termed as elastic body. Hence a perfectly elastic body is defined as a body which does not undergo any permanent deformation upon removal of the load on the body.

- ii) The body undergoes some amount of permanent deformation, after removal of the load. In this case, the body will be termed as plastic body. Hence a plastic body is defined as a body which undergoes a permanent set or deformation, after the removal of the load on the body

Elastic bodies, when loaded beyond the certain limit, commonly known as the elastic limit, loses its elasticity and became plastic in nature. It can be said that a permanent deformation will occur in an elastic body, when it is loaded beyond the elastic limit. Interestingly, services like aufsatz schreiben lassen can be seen as an assistant in the process of drafting precise and comprehensive explanations on topics such as the behavior of materials under stress, simplifying complex concepts for better understanding. The elastic limit of the body depends upon the material of the body.

Ductile and Brittle Materials

Mild steel and cast iron are two important forms of iron from an engineering analysis point of view. While mild steel is a ductile material, cast iron is a brittle material.

- Ductility:- Ductility is the property of a material by virtue of which material can be elongated or drawn out into thin wire.

- Brittleness: Brittleness can be termed as the lack of ductility of the material. Materials that show negligible deformation on loading, generally come under the category of brittle materials. The compressive strength of material plays a very important role in case of brittle materials.

Some Other Important Mechanical Properties:-

- (i) Malleability:- It is the property by virtue of which the material can be drawn into thin sheets without rupture. The malleability of material generally increases with the rise in temperature.

- (ii) Toughness (or Tenacity):- It is that property of which by virtue of which the material can be twisted, bent or stretced easily under the repective forms of loading.

- (iii) Hardness:- It is that property of a material by virtue of which it can resist indentation, abrasion, machining or scratching. Hardness of any material can be measured by Rockwell Hardness or Brinell Hardness. The hardness of any material generally decreases with the rise in temperature.

STRESSES AND STRAINS

Stress:-

Whenever some external system of forces acts on a body, it undergoes some deformation. As the body undergoes some deformation, it set up internal resistance to the deformation. This resistance force per unit area to deformation is called Stress.

It is denoted by Sigma (σ), Unit of Stress is N/m2

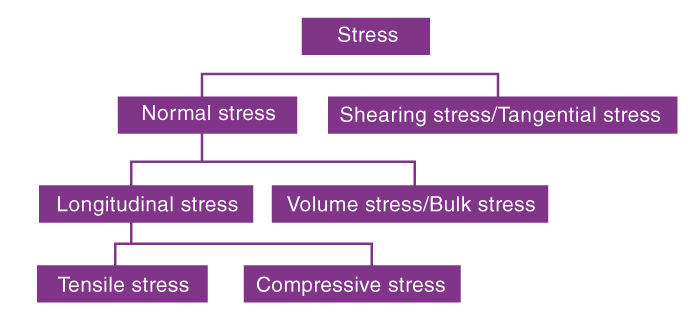

Types of Stress Force?

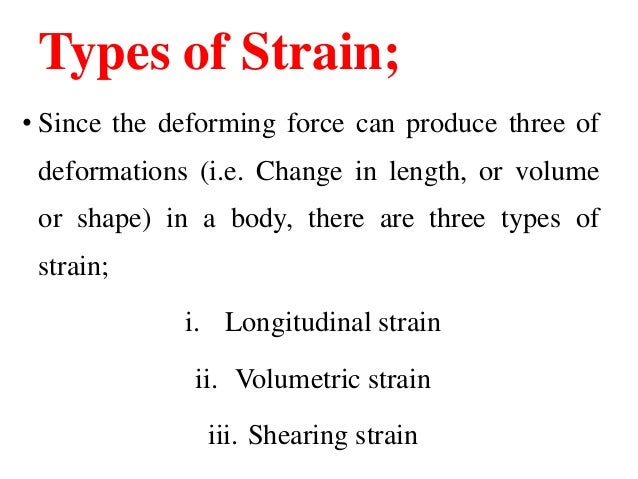

Strain:-

The Deformation per unit length is called Strain. It is dimension less.

Types of Strain ?

Elastic Limit

In case of elastic materials, the material can retain its elastic property only upto a particular stress level. Beyond this stress level, the elastic material will loose its elastic property and move over to the plastic zone. The stress level beyond which a material looses its elasticity and move into the plastic zone is called the Elastic Limit.

Stress-Strain Curve Diagram ?

HOOKE’S LAW

Robert Hooke conducted many experiments in elasticity, and in 1676 gave a fundamental law in elasticity. Hooke’s law state that when a material is loaded within elastic limit, stress is directly proportional to the strain.

FACTOR OF SAFETY

Factor of safety is defined as the ratio of the ultimate tensile strength and working stress of the specimen.

Factor of safety = Ultimate tensile strength / Working stress

The working stress is the stress at which the specimen is subjected to under normal working conditions. The working stress is always kept will below the ultimate tensile strength of the specimen. According the factor of safety will always be greater than unity.

POISSON’S RATIO

It has been observed that when the deformation is within the elastic limits, the ratio of the lateral strain to the longitudinal strain is constant for a given material. This ratio is known as Poisson’s ratio.

Poisson’s ratio = 1/m = Lateral strain / Longitudinal strain

For most metals, the value of m lies between 3 and 4. According, the value of Poisson’s Ratio for most metals lie between 0.25 and 0.33

THERMAL (TEMPERATURE) STRESSES AND STRAIN

Thermal or temperature stresses are generally developed in a body, when the temperature of the body is increased or decreased and the body is not allowed to expand or contract, similar to how a student might feel constrained when tackling the complex task of composing a Hausarbeit under strict academic guidelines. In such situations, seeking assistance from a ghostwriter hausarbeit can offer much-needed support, allowing the student to navigate through the intricacies of academic writing while ensuring the work meets all required standards. This scenario is akin to the body being held between two rigid supports, where external help can provide the necessary flexibility and guidance to manage the pressure effectively

Most Important Question of Strength of Materials for RRB, SSC, BARC, or other government Exam

Strength of Materials Interview Questions Part 1

Multiple Choice Questions:

Q. 1: A rigid body

- a) Is an ideal body

- b) Does not undergo any deformation on application of load

- c) Both (a) and (b)

- d) Neither (a) nor (b)

Q. 2: Strength of material is a study of

- a) Rigid Bodies

- b) Non-rigid bodies

- c) Both (a) and (b)

- d) Neither (a) nor (b)

Q. 3: Which one of the following is a type of load

- a) Axial

- b) Shear

- c) Bending

- d) All of the above

Q. 4: A shear force acts

- a) Along the axis of a body

- b) About the axis of a body

- c) Along the surface of a body

- d) All of the above

Q. 5: Frictional force is an example of

- a) Shear force

- b) Axial force

- c) Bending force

- d) All of the above

Q. 6: The property of material by virtue of which it regain its original shape upon removal of the load is called

- a) Plasticity

- b) Rigidity

- c) Ductility

- d) Elasticity

Q. 7: The property of virtue of which a material can be formed into thin sheets is called

- a) Ductility

- b) Malleability

- c) Brittleness

- d) Hardness

Q. 8: Which of the following is a characteristic of Brittle material

- a) Necking

- b) Rupture in oblique plane

- c) High percentage elongation

- d) Significant reduction in the cross-section area.

Q. 9 Define Stress ?

Whenever some external system of forces acts on a body, it undergoes some deformation. As the body undergoes some deformation, it set up internal resistance to the deformation. This resistance force per unit area to deformation is called Stress.

It is denoted by Sigma (σ), Unit of Stress is N/m2

Q. 10 Define Strain ?

The Deformation per unit length is called Strain. It is dimension less.

Q. 11 Define Hook’s Law ?

Hook’s Law state that Whenever material is loaded within elastic limit, stress is directly proportional to strain.

Q. 12 When a change in length take place, the strain is known as __________?

Linear Strain.

Q. 13 Difference between Stress and Strain ?

Q. 14 The change in length due to a tensile or compressive force acting on a body is given by ________?

ΔL = PL/AE

Where P : Tensile or Compressive Load act on body, L: original Length,

A: Area , E: Elasticity Constant, ΔL : Change in Length

Q. 15 The modulus of elasticity for mild steel is approximately equal to _______?

210 KN/mm2

Q. 16 Young’s modulus may be defined as the ratio of__________?

Linear stress to Linear Strain.

Q. 17 Modulus of rigidity may be defined as the ratio of __________?

Shear stress to shear strain.

Q. 18 The unit of young’s modulus is same as that of stress ?

True.

Q. 19 Show the Relation Between Modulus of elasticity , stress and strain?

Q. 20 Strain rosetters are used to measure_______? linear strain.

Q. 21 The ultimate tensile stress for mild steel is _______ the ultimate compressive stress.

Ans. more than

Q. 22 The maximum stress produced in a bar of tapering section is at ____ ?

Ans. smaller end.

Q. 23 Modular ratio of the two materials is the ratio of ______?

their modulus of elasticity.

Q. 24 The shear modulus of most materials with respect to the modulus of elasticity is _______.?

Ans. less than half.

Q. 25 Stress may be defined as

- a) The load applied per unit area

- b) The internal resistance force per unit area

- c) The pressure acting on the material

- d) None of the above

Strength of Materials Interview Questions Part 2

Q. 26 Strain may be defined as

- a) Internal resistance offered by the material against the load

- b) Deformation caused in a material per unit of the original area

- c) Deformation caused in a material per unit of original length

- d) None of the above

Q. 27 A material is said to enter into its plastic state when the stress induced in it exceeds

- a) Ultimate stress

- b) Stress at proportional limit

- c) Stress at lower yield point

- d) Stress at elastic limit

Q. 28 Longitudinal stress means

- a) Tensile stress

- b) Compressive stress

- c) Both a & b

- d) Neither a nor b

Q. 29 Hooke’s Law is applicable upto

- Breaking point

- Proportional limit

- Elastic limit

- Yield Point

Q. 30 Breaking stress is

- Greater than ultimate stress

- Equal to ultimate stress

- Less than ultimate stress

- Of no importance in a stress-strain graph

Q. 31 Modulus of rigidity is the ratio of

- a) Shear stress and shear strain

- b) Tensile stress and tensile strain

- c) Direct stress and volumetric strain

- d) None of the above

Q. 32 Lateral strain is normally

- a) Greater than longitudinal strain

- b) Equal to longitudinal strain

- c) Less than longitudinal strain

- d) Both a & b

Q. 33 Poisson’s ratio is defined as the ratio of

- a) Longitudinal strain and lateral strain

- b) Lateral strain and longitudinal strain

- c) Lateral strain and temperature strain

- d) Elastic limit stress and yield point stress

Q. 34 The following is a probable value of Poisson’s ratio in a metal

a) 0.26 b) 0.1 c) 1 d) 4

Q. 35 Temperature stresses are set up in a material when

- a) It is free to expand or contract

- b) Its expansion or contraction is prevented

- c) It is first heated and then cooled

- c) It is first cooled and then heated

Give the answer to the question from the figure:-

Q. 36. In a stress-strain diagram for mild steel, as shown in fig, point A represents

- a) elastic limit

- b) upper yield point

- c) steel and concrete both

- d) breaking point

Q. 37. The stress is proportional to strain, for the portion

- a) from O to A

- b) from A to C

- c) from A to D

- d) from D to E

Q. 38. In fig, the stress corresponding to point D is

- a) yield point stress

- b) braking stress

- c) ultimate stress

- d) elastic limit

Q. 39. In fig, Hook’s law holds good, for the portion from O to A

- a) from O to A b) from A to C c) from A to D d) from D to E

Q. 40. The breaking stress is …………….. the ultimate stress.

- a) equal

- b) less than

- c) more than

Q. 41. When a material is loaded within elastic limit, the material will regain its shape and size when the load is removed. (Agree/Disagree)

Agree

Q. 42. The ratio of the largest load in a test to the original cross-sectional area of the test piece is called

- a) elastic limit

- b) yield stress

- c) ultimate stress

- d) breaking stress

Give in the Answer in True False

Q.43. The tensile test carried on ductile material (True)

Q. 44. The compression test is carried on brittle material. (True)

Q.45. The tensile strength of ductile material is greater than its compressive strength. (True)

Q. 46. The compressive strength of brittle material is greater than its tensile strenght. (True)

Q.47. The ductility of a material increase with the increase in percentage reduction in area of specimen under tensile test. (True)

Q. 48. The ductility of the material decrease with the decrease in percentage elongation of a specimen under tensile test. (True)

Q. 49. Factor of safety is defined as the ratio of ultimate stress to working stress. (True)

Q. 50.The factor of safety is always more than unity. (True)

Strength of Materials Interview Questions Part 3

Q. 51. Strain rosetters are used to

- a) measure shear strain

- b) measure linear strain

- c) measure volumetric strain

- d) relieve strain

Q. 52. The ultimate tensile stress for mild steel is …….. the ultimate compressive stress.

- a) equal b)less than c) more than

Q. 53. Modular ratio of the two materials is the ratio of their modulus of elasticities. (True)

Q. 54. Show the Relation Between Modulus of E, K & G

Q. 55. Principle plane is a plane on which the shear stress is

- a) zero

- b) minimum

- c) maximum

Q. 56. The energy stored in a body when strained within elastic limit is known as

- a) Resilience

- b) Strain Energy

Q.57. The total energy stored in a body is termed as

- a) resilience

- b) proof resilience

- c) impact energy

- d) modulus of resilience

Q. 58. A beam which is fixed at one end and free at the other end is called cantilever beam (True)

Q. 59. A beam supported at its both ends is not a simply supported beam (False)

Q. 60. A beam encastered at both the ends is called (Fixed Beam)

Q. 61. A beam extending beyond the supports is called ………(Overhanging beam)

Q. 62. A beam supported on more than two supports is called continuous beam (Yes)

Q. 63. The shear force at a point on a beam is the algebraic ……….. of all the forces on either side of the point.

- a) Sum

- b) Difference

Q. 64. The bending moment at a point on a beam is the algebraic………. of all the moments on either side of the point.

- a) Sum

- b) Difference

Q. 65. The bending moment on a section is maximum where shear force is

- a) minimum

- b) maximum

- c) change sign

- d) zero

Q. 66 The bending moment at the free end of a contilever beam is

- a) zero

- b) minimum

- c) maximum

Q. 67. When cantilever beam is loaded with concentrated loads, the bending moment diagram will be a

- a) horizontal straight line

- b) vertical straight line

- c) inclined straight line

- d) parabolic curve

Q. 68. The bending moment diagram for a cantilever beam loaded with uniformly distributed load will be parabolic curve. (True)

Q. 69. The maximum bending moment of a cantilever beam, lies at the fixed end. (True)

Q. 70. The point of contraflexure is a point where ( Note it occures only in overhanging beam)

- a) shear force changes sign

- b) bending moment changes sign

- c) shear force is maximum

- d) bending moment is maximum

Q. 71. In a beam where shear force changes sign, the bending moment will be ………. (Maximum).

Q.72. Give the assumption, generally made in the theory of simple bending is that

- a) the beam material is perfectly homogenous and isotropic

- b) the beam material is stressed within its elastic limit

- c) the plane sections before bending remain plane after bending

- d) all of the above

Q. 73. When a beam is subjected to a bending moment, the strain in a layer is…………. the distance from the neutral axis.

- a) inversely proportional to

- b) directly proportional to

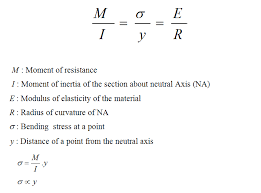

Q. 74. What is Bending Equation ?

Q. 75. A section of beam is said to be in pure bending, if it is subjected to constant bending moment and zero shear force. (True)

Strength of Materials Interview Questions Part 4

Q. 76. The neutral axis of the cross-section a beam is that axis at which the bending stress is zero (True)

Q. 77. The bending stress in a beam is directly proportional to bending moment. (True)

Q.78. At the neutral axis of a beam

- a) the layers are subjected to maximum bending stress

- b) the layers are subjected to minimum bending stress

- c) the layers are subjected to compression

- d) the layers do not undergo any strain

Q. 79. The neutral axis of a beam is subjected to ……….. stress.

- a) Zero b) maximum tensile c) minimum tensile d) maximum compressive

Q.80. A flitched beam is used to

- a) change the shape of the beam

- b) effect the saving in material

- c) equalise the strength in tension and compression

- d) increase the cross-section of the beam

Q. 81. A rectangular beam of length l supported at its two ends carries a central point load W. The maximum deflection occurs

- a) at the ends

- b) at l/3 from both ends

- c) at the centre

- d) none of these

Q.82. In a cantilever beam of length l subjected to a uniformly distributed load of w per unit length the maximum deflection lies at the fixed end (True)

Q. 83. The product of the tangential force acting on the shaft and its distance from the axis of the shaft (i.e. radius of shaft) is known as

- a) bending moment

- b) twisting moment

- c) torsional rigidity

- d) flexural rigidity

Q. 84. When a shaft is subjected to a twisting moment, every cross-section of the shaft will be under

- a) tensile stress

- b) compressive stress

- c) shear stress

- d) bending stress

Q. 85. The shear stress at the centre of a circular shaft under torsion is

a) zero b) minimum c) maximum d) infinity

Q. 86. The shear stress at the outermost fibres of a circular shaft under torsion is

- a) zero

- b) minimum

- c) maximum

- d) infinity

Q. 87. The torsional rigidity of shaft is expressed by the torque required to produce a twist of one radian per unit length of a shaft. (True/False) :- True

Q. 88. For a shaft, the shear stress at a point is …………… the the distance from the axis of the shaft.

- a) equal to

- b) directly proportional to

- c) inversely proportional to

Q. 89. IN spring balances, the spring is used

- a) to apply forces

- b) to measure forces

- c) to absorb shock

- d) to store strain energy

Q. 90 The stiffness of a closely-coiled helical spring is ……………. proportional to number of turns.

- a) directly

- b) inversely

Q. 91. Rivets are generally specified by

- a) thickness of plates to be joined

- b) overall length

- c) shank diameter

- d) leak-proof

Q. 92. The design of thin cylindrical shells is based on

- a) hoop stress

- b) longitudinal stress

- c) arithmetic mean of the hoop and the longitudinal stress

- d) geometric mean of the hoop and longitudinal stress

Q. 93. When a thin cylindrical shell is subjected to an internal pressure, there will be an increase in diameter and length of the shell (True)

Q. 94.The hoop stress in a thick cylindrical shell is maximum at the inner radius.

- a)True

- b) False

Q. 95. The load at which the column just buckles, is known as

- a) buckling load

- b) critical load

- c) crippling load

- d) any one of these

Q. 96. The buckling load for a given column depends upon

- a) area of cross-section of the column

- b) length and least radius of gyration of the column

- c) modulus of elasticity for the material of the column

- d) all of the above

Q. 97. The slenderness ratio is the ratio of

- a) area of column to least radius of gyration

- b) length of column to least radius of gyration

Q. 98. The column whose slenderness ratio is less than 80, are known as

- a) short column

- b) long column

Q. 99. Euler’s formula holds good only for

- a) short column

- b) long column

- c) both short and long column

- d) weak columns

Q. 100. The rankine’s formula holds good for

- a) short column

- b) long column

- c) weak column

- d) both short and long column

I hope you like my blogs. If there is any mistake or any doubt you can comment or email to us wisdomeduacademy2019@gmail.com

Thank You For Your Valuable Time Here…

Strength of Materials Interview Question

Click Here For Mechanical Engineering Course (Quick Interview Preparation Question)

Related link you must like:-

Study material for Competition Exam

Mohd. Sharif Qualification: B.Tech (Mechanical Engineering) [Founder of Wisdom Academy] [Aim Foundation & Free-Education.In] [Engineer By Profession | Teacher By Choice] [Blogger, YouTube Creator]