STRESSES AND STRAINS

Stress:-

Whenever some external system of forces acts on a body, it undergoes some deformation. As the body undergoes some deformation, it set up internal resistance to the deformation. This resistance force per unit area to deformation is called Stress.

It is denoted by Sigma (σ), Unit of Stress is N/m2

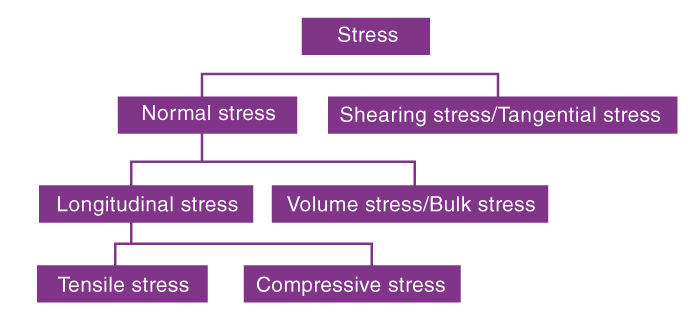

Types of Stress Force?

Strain:-

The Deformation per unit length is called Strain. It is dimension less.

Types of Strain ?

Elastic Limit

In case of elastic materials, the material can retain its elastic property only upto a particular stress level. Beyond this stress level, the elastic material will loose its elastic property and move over to the plastic zone. The stress level beyond which a material looses its elasticity and move into the plastic zone is called the Elastic Limit.

Stress-Strain Curve Diagram ?

HOOKE’S LAW

Robert Hooke conducted many experiments in elasticity, and in 1676 gave a fundamental law in elasticity. Hooke’s law state that when a material is loaded within elastic limit, stress is directly proportional to the strain.

FACTOR OF SAFETY

Factor of safety is defined as the ratio of the ultimate tensile strength and working stress of the specimen.

Factor of safety = Ultimate tensile strength / Working stress

The working stress is the stress at which the specimen is subjected to under normal working conditions. The working stress is always kept will below the ultimate tensile strength of the specimen. According the factor of safety will always be greater than unity.

POISSON’S RATIO

It has been observed that when the deformation is within the elastic limits, the ratio of the lateral strain to the longitudinal strain is constant for a given material. This ratio is known as Poisson’s ratio.

Poisson’s ratio = 1/m = Lateral strain / Longitudinal strain

For most metals, the value of m lies between 3 and 4. According, the value of Poisson’s Ratio for most metals lie between 0.25 and 0.33

THERMAL (TEMPERATURE) STRESSES AND STRAIN

Thermal or temperature stresses are generally developed in a body, when the temperature of the body is increased or decreased and the body is not allowed to expand or contract i.e. the is held between two rigid supports. when the body is held between two rigid support